The

following topics are covered in this section:

|

|||||||||||||||

Inputs

|

|||||||||||||||

Interfacing Digital Inputs to TTL

|

|||||||||||||||

Before we

can discuss interfacing digital signals to TTL inputs, we must remind

ourselves of the voltage and current levels of a TTL input.

|

|||||||||||||||

The logic

levels for TTL inputs are as follows:

|

|||||||||||||||

|

|||||||||||||||

When a

HIGH is applied to a TTL input it draws very little current (about 40 uA).

When a LOW is applied to a TTL input it sources approximately 1.6 mA.

|

|||||||||||||||

Therefore,

when interfacing a digital input (which will be either HIGH or LOW) to TTL we

must ensure it meets the requirements of a TTL input.

|

|||||||||||||||

The

diagram below shows how to interface a digital input (ie; either high or low)

to TTL.

|

|||||||||||||||

When the

digital input is HIGH the transistor will be turned on. This results in a

direct path from the port pin to ground, therefore the pin is logic 0. When

the digital input is LOW the transistor is off which means there is no path

for current from the collector to the emitter, therefore the port pin will

read 5V.

|

|||||||||||||||

This circuit

results in logic inversion, but this should not be a problem as inverting the

port pin through software is very easy.

|

|||||||||||||||

When the

transistor is on the port pin is connected directly to ground. Therefore

there is a path for the 1.6 mA from the port pin (TTL current when input is

LOW). The 10 K emitter resistor ensures the current from the supply is kept

low, an important consideration in battery powered devices.

|

|||||||||||||||

When the

transistor is off the port pin is at 5 V (in reality it will not be exactly

5V because a transistor is never fully off and a small current will flow

through the emitter resistor, resulting in a small voltage drop across the

resistor - but the voltage level on the resistor will still be close to 5 V).

Since there is very little current flowing, power consumption is kept low.

Also, as mentioned above, a TTL input draws very little current when a HIGH

is applied to it, so this circuit satisfies the requirements of a TTL input

and keeps power consumption at a minimum.

|

|||||||||||||||

The digital HIGH need not be TTL level inputs.

|

|||||||||||||||

The HIGH

voltage applied to the base of the transistor does not have to be 5V. For

example, the input circuit could be from temperature sensor that produces a

HIGH voltage when the temperature exceeds a certain value. The voltage level

from this circuit could be any voltage that is high enough to turn on the

transistor (say, 12V for example) and the value of the base resistor can be

calculated to suit. Because the voltage applied to the emitter resistor is 5

V the digital HIGH from the sensor circuit is level-shifted to suit a TTL

input.

|

|||||||||||||||

Switches

|

|||||||||||||||

The

circuit above is actually interfacing an electronic switch, the transistor,

to a TTL input. We can interface a physical switch in exactly the same way, as

shown below.

|

|||||||||||||||

When the

switch is open, no current flows through the resistor and therefore the

voltage on the microcontroller pin is 5 V. When the switch is closed the pin

is connected directly to ground. As before, when the TTL input is HIGH practically

no current flows in the circuit and when the input is LOW there is a direct

current for the 1.6 mA that may flow from the pin.

|

|||||||||||||||

Switch Bounce

|

|||||||||||||||

When a

physical switch is closed the contacts bounce open and closed rapidly for

about 20 to 30 ms, as illustrated below.

|

|||||||||||||||

The

opening of a switch is clean and without bounce. However, when a switch is

closed the contacts bounce open and closed for about 30 ms. While this is a

very short time in human terms it is a very long time for a microcontroller

(the basic 8051 running on a system clock of 12 MHz executes a 1-byte

instruction in 1 us). Without switch debouncing, the microcontroller would

'think' the switch was opened and closed many times. Imagine if a push-button

switch was being used to increment the output from a microcontrolled power

supply. If the switch was connected to the microcontroller without switch

bounce then a user pressing the switch once would actually result in the

output voltage being increased many times because the microcontroller would

respond as if the switch had been pressed many times.

|

|||||||||||||||

Hardware Switch Debounce

|

|||||||||||||||

One method

of hardware debounce is shown below.

|

|||||||||||||||

As can be

seen from the waveforms above, when the switch is closed the capacitor

voltage drops to 0 V. When the switch bounces open the capacitor begins to

charge back up to 5 V, but due to the RC constant, it cannot charge beyond

the schmitt trigger's HIGH reference voltage before the switch bounces closed

again. Once the switch closes, the capacitor again drops to 0 V. Since the

voltage on the capacitor never goes beyond the trigger's HIGH reference

voltage during the switch bounce, the output of the trigger remains LOW and

the switch bounce is not seen on the port pin.

|

|||||||||||||||

When the

switch is physically opened the capacitor has plenty of time to charge beyond

the trigger's HIGH reference voltage, at which point the trigger output goes

HIGH and this is seen on the port pin.

|

|||||||||||||||

Software Switch Debounce

|

|||||||||||||||

Hardware

debounce requires extra circuitry. With small devices, this extra hardware

may not be tolerated. In most cases, software debounce is more than adequate.

Software debounce simply incorporates a delay of about 30 ms while the switch

bounces. In other words, when a key press is detected, the system delays for

about 30 ms before processing the input. By then the switch will have stopped

bouncing and the microcontroller will only process the initial switch

contact.

|

|||||||||||||||

Delaying

for about 30 ms will not be noticed by the user, but the microcontroller

could do quite a bit of work in that time. Therefore, in a multifunction

system it is more efficient to initialise a timer and start it so that it

will overflow and generate an interrupt 30 ms after the switch was pressed.

In that way, the controller can be doing some other work while the switch

bounces.

|

|||||||||||||||

In the

above flow chart diagrams, processing the key press is handled in the ISR.

This may not be the case in a multifunction system. It is more likely that

the ISR would set a flag to let the main program know that a key has been

pressed (or, in an RTOS system, to move a process from the waiting state to

the ready state).

|

|||||||||||||||

Keypads

|

|||||||||||||||

Keypads

are assembled in a matrix form, as illustrated below.

|

|||||||||||||||

The above

diagram shows a 4 X 4 keypad - 16 switches configured

in 4 columns and 4 rows.

|

|||||||||||||||

In the

default state (all switches open) there is no connection between the rows and

columns. When a switch is pressed a connection between the switch's row and

the switch's column is made.

|

|||||||||||||||

Keypad Decoder

|

|||||||||||||||

Many

keypads are built with an onboard decoder that scans the keypad and, if a key

is pressed, returns a number identifying the key. Alternatively, a keypad

decoder chip can be purchased separately and interfaced with a keypad. The

diagram below shows a 4 X 4 keypad

interfaced with such a decoder.

|

|||||||||||||||

The

decoder is shown connected to the 8051, as a suggestion. Obviously, the

outputs from the decoder don't need to go to the LSBs of P1, nor does the

data available line (DA) need to be connected to the external 0 interrupt

line. However, the above configuration is one way of interfacing a 4 X 4

keypad decoder to the 8051.

|

|||||||||||||||

The

decoder has 8 inputs; the 4 X inputs are connected to the 4 keypad columns

while the Y inputs are connected to the 4 keypad rows. Not shown in the

diagram are pins for connecting capacitors to the decoder. These capacitors

govern the rate at which the keypad is scanned.

|

|||||||||||||||

When a key

is pressed the 4-bit code for the key (there are 16 keys, therefore there are

codes 0000 to 1111 in binary) appears on the four output lines (and in this

case will appear on the 4 LSBs of P1) and the data available line (DA) goes

LOW. If connected to an external interrupt line (in this case, the INT0-bar

line) the microcontroller will be interrupted when a key is pressed. The ISR

could then read the 4 LSBs of P1 and process the data.

|

|||||||||||||||

The

decoder chip takes care of switch debounce, therefore the programmer is freed

from this responsibility, which is an advantage of using a decoder chip.

|

|||||||||||||||

Software Decoder

|

|||||||||||||||

The above

decoder function can be implemented in software. The keypad could be

interfaced with the 8051 as detailed below.

|

|||||||||||||||

With the

above configuration, an interrupt is generated on the INT0-bar line when a

key is pressed. We will deal with how this works in a moment. Firstly, let's

see how the keyboard is scanned.

|

|||||||||||||||

The steps

are:

|

|||||||||||||||

|

|||||||||||||||

Scanning a

row is achieved by applying 0 V to the port pin for that row and 5 V to the

other three rows, then scanning each individual column to see if one of them

is LOW. If it is, then the key at the junction between the current row and

column being scanned is the pressed key.

|

|||||||||||||||

|

|||||||||||||||

For

example, let's say the key being pressed is key 6. When scanning the first

row, P1.0 will be cleared while the other 3 rows (P1.1, P1.2 and P1.3) are

set, as detailed in the diagram below.

|

|||||||||||||||

Since no

key in this row is closed there is no path for current through any of the

pull-up resistors and all 4 columns (on P1.4 to P1.7) are HIGH. Therefore,

the key pressed was not found while scanning row 1.

|

|||||||||||||||

The

diagram below illustrates scanning row 2. (Note that key 6 is still closed.)

|

|||||||||||||||

In this

case, column 3 is connected through the closed switch to row 2. Since row 2

is LOW, column 3 is LOW.

|

|||||||||||||||

A series

of flowcharts for implementing software keypad scan is given below:

|

|||||||||||||||

The keypad

is initialised in the main program; all rows are cleared. Therefore, when a

key is pressed, since all rows are LOW, then one of the columns (the one

containing the key that has been pressed) will be connected to 0 V. This

logic 0 into the AND gate will result in a logic 0 out. Since the output of

the AND gate is connected to INT0-bar, a key press will result in an external

0 interrupt.

|

|||||||||||||||

The

keyPressedISR is the ISR for dealing with an external 0 interrupt. The first

thing this ISR does is disable the external 0 interrupt and call a 30 ms

(typical) delay subroutine. When the delay subroutine returns the key will

have stopped bouncing and the keypad can now be scanned.

|

|||||||||||||||

In this

example, the value of the key pressed (0 to 15) will be stored in R0.

Therefore, at the start of the scanKeypad subroutine R0 is set to 0. Row 1 is

cleared while the other three rows are set. The columnScan subroutine is then

called. It tests the status of each column. If the first column is 0 then,

since we are currently scanning row 1, key 0 was pressed and its value is in

R0. Therefore the keyFound flag is set and the subroutine returns.

|

|||||||||||||||

If the

first column is not 0, R0 is incremented (it now holds 1) and the next column

is tested. If it is 0 then key 1 was pressed and this value is in R0 -

therefore the keyFound flag is set and the subroutine returns.

|

|||||||||||||||

This is

repeated for all columns until the key is found.

|

|||||||||||||||

If none of

the four columns is 0 then the key pressed is not in this row and the

subroutine returns without setting the keyFound flag.

|

|||||||||||||||

When

columnScan returns, the keyFound flag is tested. If it is not 1 then the key

was not found and the scanKeypad subroutine continues with the next row.

Throughout this process, R0 is incremented so that when the key is finally

found R0 will contain the value of that key.

|

|||||||||||||||

When

scanKeypad returns to the ISR the value of the key is in R0. The ISR then

calls a subroutine to wait for the key to be released. If we do not wait for

the key to be released and immediately enable the external 0 interrupt, then

the system will react as if the key was pressed again. Even if a user presses

and releases the key as quickly as possible, the microcontroller will have

executed the ISR and enabled the INT0 interrupt before the user actually

released the key. Therefore we wait for the user to release the key before

proceeding.

|

|||||||||||||||

The

waitForKeyRelease subroutine is quite simple. All four rows are cleared so

that no matter which key is pressed, one of the columns will be 0 which will

result in a 0 out of the AND gate to the INT0-bar line. Therefore, while the

key is held down this line will be 0. Once the key is released then all four

columns will be 1 resulting in a 1 at INT0-bar and the subroutine returns.

|

|||||||||||||||

The

external 0 interrupt flag (IE0) is then cleared because it may have been set

as the key bounces and as we scanned the keyboard (remember, disabling an

interrupt does not prevent the interrupt from occurring - a 0 on INT0 will

still set the flag, IE0). If we did not clear this flag, once we again enable

the external 0 interrupt the system would again vector to keyPressedISR.

|

|||||||||||||||

The

processKeyFlag is then set to alert the main program to the fact that a key

was pressed. The main program can then retrieve the value of the key from R0

and process it in whatever way the system design requires.

|

|||||||||||||||

Separate Debounce Interrupt

|

|||||||||||||||

One of the

problems with the above implementation is the fact that the system is held in

a 30 ms delay while the key bounces. The microcontroller could be doing

something a lot more useful in that time (remember, a basic 8051 running on a

system clock of 12 MHz could execute 30,000 1-byte instructions in that

time). One way would be to set one of the timers to overflow in 30 ms, enable

the timer's interrupt, start the timer and exit the keyPressedISR. The

timer's ISR could then execute the rest of the keypad scan process (ie;

what's left in keyPressedISR above goes into the timer's ISR instead).

|

|||||||||||||||

Doing Nothing While the Key is Held Down

|

|||||||||||||||

In the

above implementation the system is held up doing nothing as it waits for the

key to be released. Even in the short space of time of an ordinary key press,

the controller could be doing something useful, but it is even more wasteful

if you imagine a user holding the key down for a long time. One solution with

the 8051 would be to initialise the external 0 interrupt as negative-edge

activated rather than low-level activated. In this case, the

waitForKeyRelease subroutine would not be needed at all. Once the external 0

interrupt is again enabled in keyPressedISR another external 0 interrupt

could not occur until the key was released and another (or the same one)

pressed; only this would result in a negative edge on INT0-bar.

|

|||||||||||||||

Note: there is one other task performed by

waitForKeyRelease - in performing its function it resets all four rows. If

this subroutine is removed, as suggested, then the code for clearing the rows

(ie; CLR P1.0; CLR P1.1; CLR P1.2; CLR P1.3) must be included in

keyPressedISR so that the system is then ready for the next key press.

|

|||||||||||||||

ADC Interfacing

|

|||||||||||||||

The

schematic symbol for a typical analogue-to-digital converter is shown below.

On the right is an illustration of how the ADC may be interfaced with the

8051.

|

|||||||||||||||

The

function of the ADC pins are as follows:

|

|||||||||||||||

|

|||||||||||||||

In the

above example of interfacing the ADC to the 8051, the CS-bar line is

connected to ground to permanently enable the chip. The INTR-bar line goes

LOW once a conversion is complete, therefore it is connected to one of the

external interrupt pins on the 8051. In this way, the 8051 will be

interrupted when a conversion is complete and data is ready for reading.

|

|||||||||||||||

The data

lines are tri-state (hence the inverted triangle symbol) which means this

chip can be memory mapped and the data lines can be connected directly to the

data bus. In the above example the data lines are connected to port 1, but

since they are tri-state the port can also be used for something else. Only

when the conversion is complete is P2.0 cleared which enables the data lines

and the analogue conversion appears on port 1.

|

|||||||||||||||

The WR-bar

line is used for starting a conversion. Clearing this line resets the

internal successive-approximation register and the 8-bit shift register. When

the line is set conversion begins.

|

|||||||||||||||

Therefore,

taking a reading from the ADC is a two step process:

|

|||||||||||||||

|

|||||||||||||||

Using an

interrupt allows the microcontroller to do some work during the 100 us it

takes to convert the analogue input into digital.

|

|||||||||||||||

Outputs

|

|||||||||||||||

We will

now look at interfacing output devices to microcontroller ports, focusing on

the following topics:

|

|||||||||||||||

|

|||||||||||||||

TTL Compatibility

|

|||||||||||||||

When

discussing interfacing to TTL inputs above, we noted the current sinked by a

TTL input when the input is HIGH is approximately 40 uA. Since the fan-out of

TTL is 10, the maximum current sourced by a TTL output HIGH is 400 uA.

|

|||||||||||||||

The

current sourced by a TTL input when the input is LOW is 1.6 mA, therefore (with

a fan-out of 10) the maximum current sinking for a TTL output LOW is 16 mA.

|

|||||||||||||||

LEDS

|

|||||||||||||||

Therefore,

when interfacing an LED to a TTL output, the maximum current through the LED

is 16 mA. The circuit below shows how to interface an LED to a microcontroller

port pin.

|

|||||||||||||||

|

|||||||||||||||

As

explained, this limits the LED on current to 16 mA, which in most cases is

adequate. However, if more current is required, the second circuit shown

above may be used. Note that both circuits result in the microcontroller port

pin sinking current when the LED is on, which is desirable as port pins will

sink a lot more current than they will source.

|

|||||||||||||||

7-segment Displays

|

|||||||||||||||

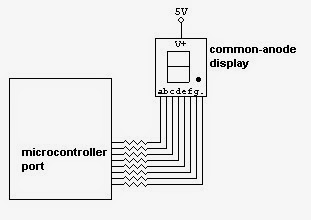

Interfacing

a single 7-segment display to a microcontroller port is done in the same

manner as interfacing a single LED. Again, the LEDs can be connected directly

to the port pins or, if high current LEDs are being used, they can be

connected through p-n-p transistors. Both methods are detailed below.

|

|||||||||||||||

|

|||||||||||||||

Multiplexing

|

|||||||||||||||

It is

often necessary to interface a number of 7-segment displays to a

microcontroller. Rather than use a separate port for each display, all of the

displays are connected to the same port and other port pins are used for

switching on one display at a time.

|

|||||||||||||||

As long as the displays are turned on and off fast

enough, to the eye it will seem as if they are all on together. A timer

interrupt could be used to switch from one display to the next. For example,

timer zero could be set to interrupt once every five milliseconds. The

operation of the timer zero ISR would be:

|

|||||||||||||||

DC Motors

|

|||||||||||||||

An

interfacing method for turning on and off a DC motor via a microcontroller is

shown below.

|

|||||||||||||||

However,

the above circuit will only work for a 5 V motor. If the supply voltage is

changed (for example, if the supply is changed to 12 V to run a 12 V motor)

then the motor will be on all the time because 5 V applied to the base of the

p-n-p transistor is not enough to turn it off.

|

|||||||||||||||

To

interface to larger motors the following circuit may be used.

|

|||||||||||||||

In the

above example a 12 V DC motor is interfaced to a microcontroller. When the

port pin is set (ie; is equal to 5 V) the p-n-p transistor is off which means

the n-p-n transistor is also off. Therefore there is no path for current

through the motor and the motor is off.

|

|||||||||||||||

When the

port pin is cleared the p-n-p transistor is on. This turns on the n-p-n

transistor which allows current to flow through the motor to ground; the

motor is on.

|

|||||||||||||||

The value

of R2 needs to be carefully chosen; too high and the current into the base of

the n-p-n transistor will not be enough to turn on the transistor, too low

and the circuit draws too much current.

|

|||||||||||||||

Bi-directional DC Motor

|

|||||||||||||||

A circuit

diagram for interfacing a 12V DC motor to a microcontroller in a way that

allows the controller to not only turn on and off the motor but also to set

the direction in which the motor runs when it is on, is given below.

|

|||||||||||||||

The

circuit is made up of a bridge. If both sides of the motor are at the same

voltage the motor is off. So, if T1 and T3 are on, both sides of the motor

are connected to 12 V and the motor is off. If T2 and T4 are on both sides of

the motor are connected to ground and, again, the motor is off.

|

|||||||||||||||

If T1 and

T4 are on then the left side of the motor is at 12 V and the right side is at

ground, therefore the motor runs in one direction. We will call this forward.

|

|||||||||||||||

If T3 and

T2 are on then the left side of the motor is at ground and the right side is

at 12 V, therefore the motor runs in the opposite direction; ie, reverse.

|

|||||||||||||||

The

circuit is designed so that T1 and T2 cannot be on at the same time and T3

and T4 cannot be on at the same time. This is very important; if T1 and T2

were on at the same time there would be a short circuit between 12 V and

ground and the transistors would burn out. The same is true for T3 and T4.

|

|||||||||||||||

The truth

table for the circuit with its two inputs, A and B, is given

below.

|

|||||||||||||||

|

|||||||||||||||

An

explanation of the four entries in the table is given below:

|

|||||||||||||||

|

|||||||||||||||

1/18/2015

Peripheral Interfacing EdSim51 simulator

Subscribe to:

Posts (Atom)